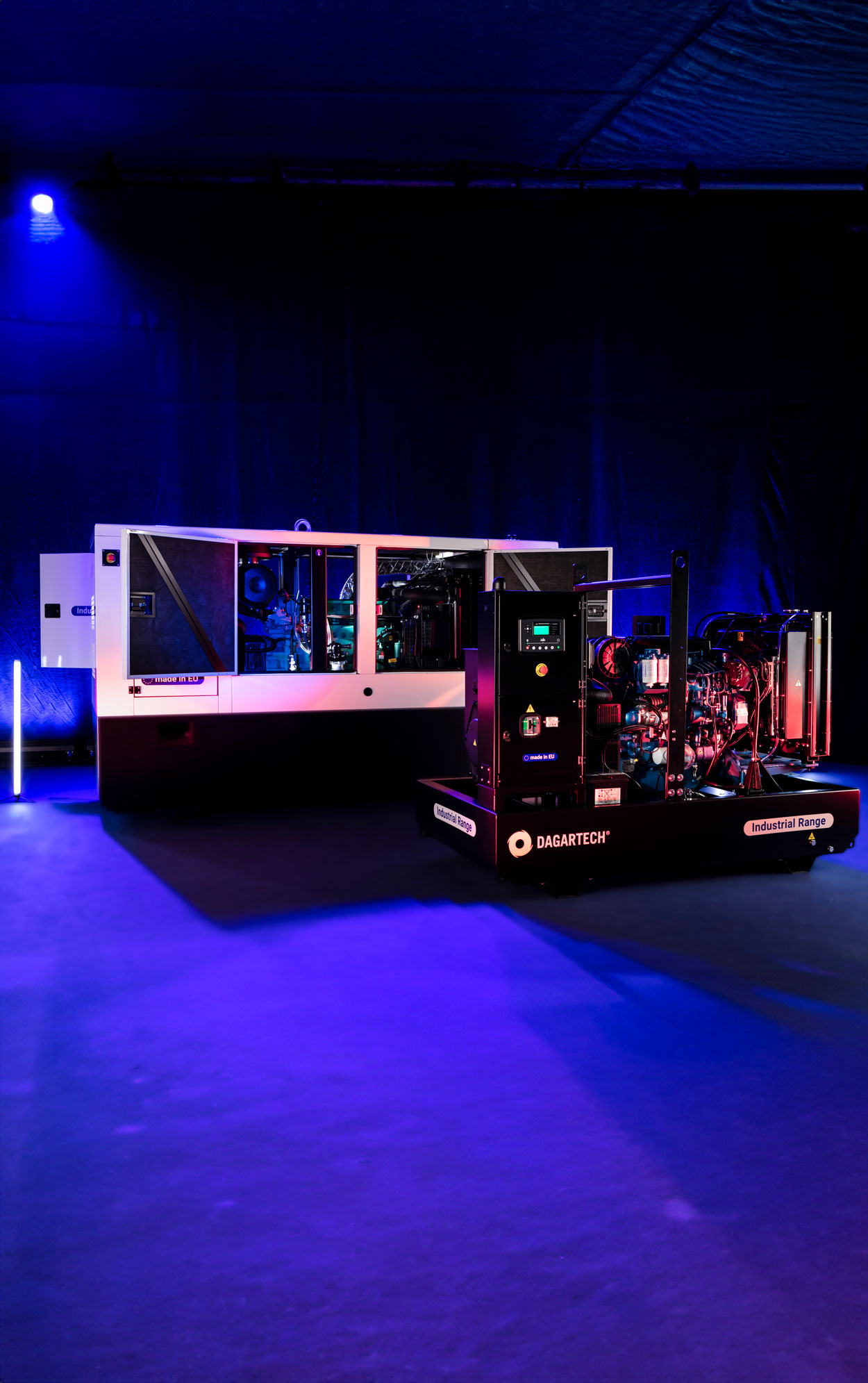

- Dagartech, a company specialised in customised energy solutions, proposes the key points to take into account when purchasing a generator.

Purchasing a generator set is an investment with a certain significance, which also affects the proper operation of critical installations. For this reason, a thorough analysis should be carried out on the circumstances and needs associated with its purchase, to ensure that they are satisfied in the best way possible.

Below, Dagartech, a company specialised in customised energy solutions, details the main aspects related with this purchase process, taking into account the 10 most critical points.

STEP 1: Having the correct power rating of the generator

Before addressing aspects related with the supply scope or features that the generator must include, it is essential to estimate the power that the consumers of the installation will require and which the generator unit must therefore be capable of covering.

Keeping in mind the peak staring currents

At this point, it is not only necessary to know the power that these will require during operation, but the peak starting currents of the inductive loads must also be taken into account (example: pumps, cranes, lifts, etc.). In these cases, the start-up intensity is usually estimated at 3 times the nominal current. When there are frequency converters, this is rounded to 2.5 times the nominal or working current.

Will all charges intervene at the same time?

Although multiplying the power required by certain charges by 3 may alarm us, it is also important to know whether or not the generator set has to deliver the power to all of them simultaneously.

To understand it better, imagine that the generator set(s) required will supply energy to a hotel in an emergency; that is, these generators will be installed to guarantee the supply in a hotel complex so that it can function during a grid failure. It is reasonable to think that not all lights in the hotel will be turned on at the same time, along with the lifts, kitchen appliances, hair dryers, air conditioning, etc.

If the power rating of the generator is the sum of all charges of the establishment, the device would be considerably oversized, making the project unnecessarily expensive and leading to an inefficient installation. Additionally, in the long run, it would also have a negative impact on the proper operation and preservation of the generator set.

Although the operating hours of an emergency generator are certainly low – today access to the electrical grid in developed companies is practically total and very stable – making a generator work on a sustained basis at low power (power demand under 30% of its “capacity”) leads to a short-term deterioration of the generator unit and causes the need to carry out maintenance work.

The solution requires application of a simultaneity factor to the installation, so that the rating of the generator is carried out based on the real power needs of the installation.

It is important to know whether the generator unit has to deliver power to all charges simultaneously.

STEP 2: Determine whether the generator will be a source of continuous or emergency supply in the installation

In the case presented above, the generator would start operating in an emergency situation (grid failure). However, another critical point that must be considered when selecting a generator is the type of application. Will the generator set be the main power source and operate continuously? Is it for emergency use?

The ISO 8528 standard classifies generators based on them having a general operating mode, continuous operation with constant charge, continuous operation with variable charge, during a certain time at a constant charge, or during a certain time with variable charge.

It is critical to understand the type of application we are addressing, as the load factor (% of time x % load) associated with each application is different, as well as the number of hours of operation applicable in each case, or the need to apply safety factors.

STEP 3: Knowing whether it is a single-phase or three-phase installation

Another aspect to take into account is whether the installation is single-phase or three-phase. This factor is completely independent of whether the engine is petrol or diesel.

Single-phase installations are different from three-phase installations as the former generate power through a single magnetic field, while the latter do so through three magnetic fields at 120º angles.

In general, there are no single-phase installations above 10-11kVA power, and this makes them preferable for use in domestic and small facility applications. This is the main reason why, the majority of single-phase generator sets available on the market do not usually exceed 25kVA ESP.

The ISO 8528 standard classifies generators based on their operating mode.

STEP 4: Choosing a diesel or petrol engine

Depending on the level of power necessary, there will be a certain margin of flexibility in applications that require low power levels. In cases where this does not exceed 25kVA, the possibility of using petrol engines may be considered. In other scenarios, the only option will be to opt for a diesel engine.

STEP 5: Knowing whether it will be operating under environmental conditions that may affect its performance

It must be taken into account that the two essential components of the generator set, the engine and alternator, may experience variations in their performance in extreme conditions of temperature, humidity and altitude. Thus, there may be drops in power (de-rating) and efficiency if we exceed certain values with regard to the three aforementioned variables. It is therefore essential to consider the conditions under which the generator unit will operate, to avoid surprises later on (example: the generator has a drop in power due to altitude and cannot meet the peak starting current of a pump).

It must be taken into account that the two essential components of the generator set, the engine and alternator, may experience variations in their performance in extreme conditions of temperature, humidity and altitude.

STEP 6: Knowing whether work will be carried out under environmental conditions that may affect performance

In line with the above, it may occur that the location where the generator is to be installed has high humidity or low temperature conditions. Beyond considering potential losses of power due to this factor, it must be considered whether the solution will require extra equipment to endure extreme environmental conditions, in order to maximise the durability and proper operation of the machine.

Applying special superficial treatments (C5-M) on the generator units to combat corrosion in marine environments, adding anti-condensation resistors to the alternator, or including engine heating systems to guarantee start-up at low temperatures are just some examples.

STEP 7: Establishing the type of start-up

Will the generator set start up by pressing a button? Will it start up automatically or due to grid failure? Or due to the input of another type of signal? This is another of the critical aspects when defining the requirements of a generator. Generators usually have manual, automatic or signal-based operating modes. The difference between each one must be checked with the manufacturer, as well as the best option for the type of application that needs to be covered.

STEP 8: Knowing whether there are restrictions on atmospheric emissions that apply to the generator

There are a growing number of restrictions on atmospheric emissions of gases and particulates, therefore it is essential to know whether there is any kind of limitation that applies to the installation. Based on this, a choice must be made between zero emissions or EU Stage 0 engines, and other EU Stage V engines, while keeping in mind the need to comply with power needs.

STEP 9: Knowing whether there are restrictions on atmospheric emissions that apply to the generator

Is the autonomy of the machine a critical factor? Will autonomy be extended with external tanks? This is another important aspect to take into account during the process of defining the specifications of the generator set.

As a general rule, the standard solutions of Dagartech guarantee autonomy of up to 8 hours at 100% charge, although the possibilities for compliance with specific requirements of the installation are (almost) infinite.

STEP 10: Maximising the efficiency of the installation by integrating remote management

Thinking in detail about the auxiliary needs of the generator set will make the difference. Customisation is associated with increased costs of the machine and this is not always the case. On many occasions, clients adopt solutions that do not meet their needs in the best way possible. Ultimately, they adapt to the generator set, when it is the generator set that must adapt to the circumstances of use of the application.

Therefore, it is very important to consider specific needs to be able to work on providing an efficient and intelligent solution.

A good example is remote management and all the benefits that this can provide.

With the generator set, information is power and cost reduction

If the generator will be installed in remote locations, having diagnostic and monitoring tools is essential for guaranteeing efficient and more suitable operation which minimises travel and unnecessary interventions.

Early detection of potential breakdowns and adequate monitoring of operating hours of the machine, its consumption or fuel replenishment are more than possible; a complete system of readings and alarms will have to be added to the generator set, as well as a control module that centralises all this information and provides it in real time.

All of this is achieved through the integration of a specific communication module, as is the case of the DSE Webnet 890, among others.

This module collects all the information from the device, such as the general operating status, oil and coolant levels, operating hours, offering fuel level alarms, engine and alternator alarms, etc. The information gathered is sent directly to a specified email address or a mobile phone. This communication module also allows monitoring and control from a PC, being widely used in control centres. From this centre, breakdowns or maintenance events can be diagnosed, thereby reducing inconvenient stoppages or travel to the location to carry out in situ diagnoses.

BONUS: Choose a trusted manufacturer that also offers you technical support and comprehensive after-sales service

The process of defining requirements is not always easy. When the project takes on a certain complexity, the best option is to rely on professionals with extensive experience to advise you and suggest the best solution in each case, doing so with quality.

Additionally, at Dagartech we also recommend selecting the generator set manufacturer considering the long-term, as maintenance, repair and component replacement works must be carried out by professionals who can quickly provide you highly technical solutions.

Dagartech provides a comprehensive service, from the initial commercial contact, design and manufacture of the machine to resolution of any issue or incident that may arise from its use.

About Dagartech

Dagartech is a Spanish company specialised in offering customised energy solutions. In this way, the company stands out for promoting unique projects that demand the maximum level of customisation, as well as designing, manufacturing and commercialising a large number of standard generator set products with powers ranging from 3 kVA to 2,000 kVA.

Dagartech generator sets are always developed considering the target application, the machine’s circumstances of use, the latest advances of the power generation market and the demands of clients. Therefore, with a clear orientation toward the needs of our clients, Dagartech has established itself as one of the main manufacturers of the Spanish market. The company currently has a stable presence in over 30 countries, with exports making up the main volume of its business.

The company has committed to innovation and has built up a human team with extensive experience in the energy generation sector. Quality and excellence form part of its present and pave the way for its future, which involves the company being certified on compliance with the requirements of the ISO 9001:2015 standard.