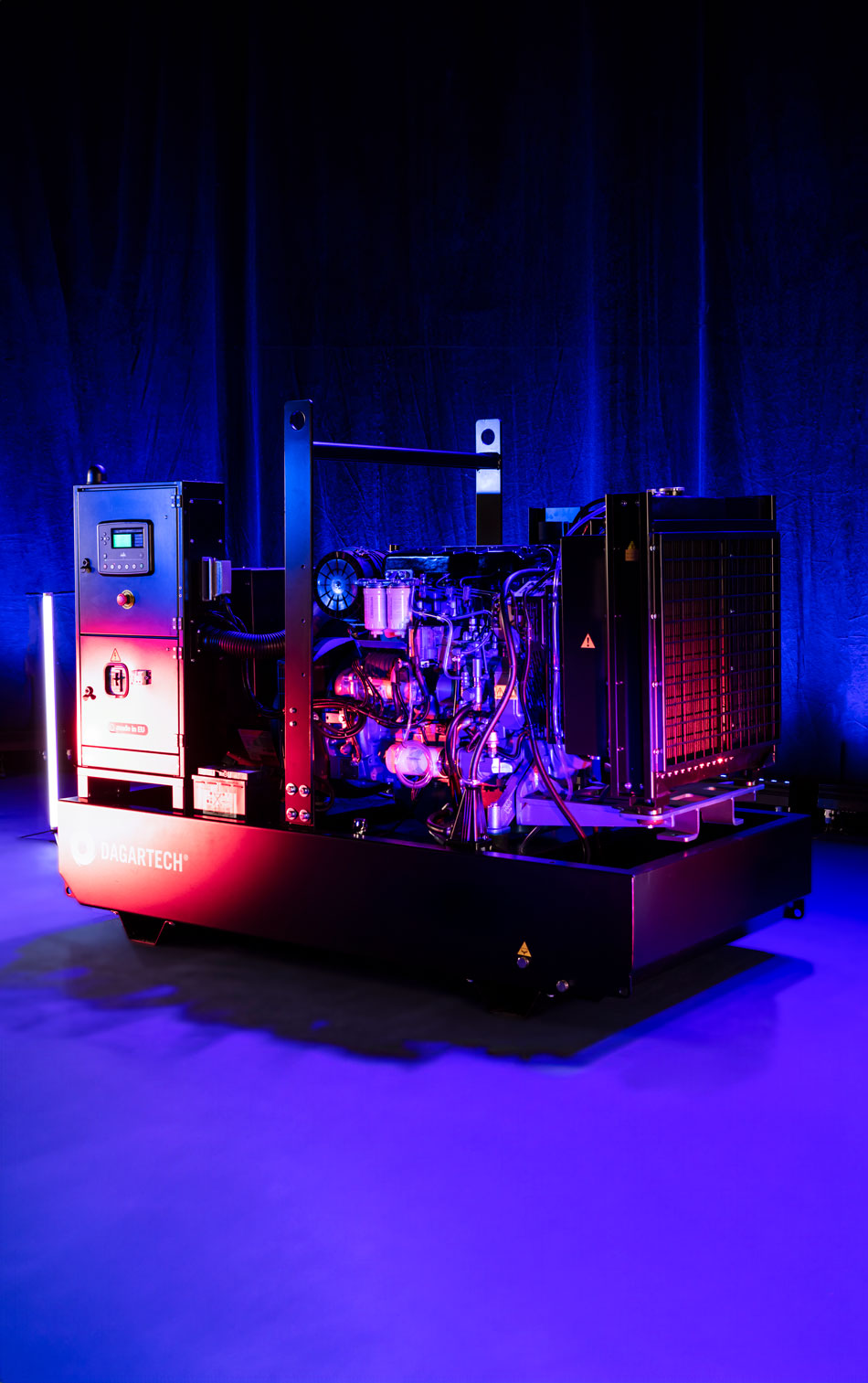

- Engines and alternators are one of the most important pairings of the energy industry.

- Dagartech generator sets include engines and alternators from renowned manufacturers, resulting in efficient and high quality solutions.

Today we celebrate Valentine’s Day, a special date where love is the most important thing. At Dagartech, we wished to pay homage to one of the most stable couples in the energy sector: the engine and the alternator.

The engine is “the heart” of the generator set. Responsible for transforming the chemical energy of the fuel into mechanical energy, in the alternator it has the perfect partner for transforming it into electricity. Both components demonstrate their full potential when they “cooperate” together, thereby guaranteeing the electricity supply in hospitals, large events and various critical infrastructure.

Because behind a great engine there is always a great alternator, today we pay homage to the latter component, of great importance in the generator set, presenting its main attributes and characteristics.

What is an alternator and how does it work?

As we mentioned at the beginning, the alternator is the component of the generator set in charge of transforming the mechanical energy of the engine into electrical energy. To better understand its operation, we must remember Faraday’s Law, which states that when a conductor is subjected to the action of a variable magnetic field, during time (t), it creates an electromotive force that passes through it, and its polarity depends on the direction of the electromagnetic field and the value of the flow.

Understanding the origin, we must focus on its architecture to understand at what point the mechanical energy of the engine is transformed into electrical energy. Thus, the alternator is made up of a hollow and fixed part, called the stator (induced) and made up of conductors, inside of which a moving part is located called the rotor (inductor). The rotor, with a cylindrical appearance, is the element that is connected to the engine. In this way, the mechanical energy from the engine is transferred to the rotor of the alternator, the alternator begins to rotate and causes an electromagnetic field in the conductors of the stator. From this process, a voltage is obtained, which will allow us to supply different electric devices.

Characteristics of alternators

Frequency and common voltages

Depending on the frequency of the grid of the country, we find 50Hz or 60Hz alternators. We do not choose this parameter ourselves, it is instead due to the location of the generator set.

Within each frequency value, we find multiple standardised voltages. The location and type of installation we are carrying out will define the use of one or another. For example, the most common three-phase voltages at 50Hz are 400/230V and 415/240V. At 60Hz, 208/120V, 220/127V and 600/347V are the most common. Likewise, the most common single-phase voltage is 230V, 240V being most common at 60Hz.

Types of connection

Depending on the number of phases (single-phase or three-phase), and the configuration of the alternator (star, delta, double delta series, etc.) we can find 6 or 12 wire alternators. However, in the industry it is most common to have 12 wire alternators, with which we can reconnect to star and triangle alternators.

Levels of insulation

In alternators, we can find three types of insulation, depending on their maximum allowable temperature. Class H insulation is common in low voltage alternators, present in generator sets, with an allowable working temperature of 180ºC.

Adjustment and excitation systems

Depending on the series and manufacturer of the alternator, we can find different excitation systems. The auxiliary winding or permanent magnet are the most common in the industry.

About Dagartech

Dagartech is a Spanish company specialised in offering customised energy solutions. In this way, the company stands out for promoting unique projects that demand the maximum level of customisation, as well as designing, manufacturing and commercialising a large number of standard generator set products with powers ranging from 3 kVA to 2,000 kVA.

Dagartech generator sets are always developed considering the target application, the machine’s circumstances of use, the latest advances of the power generation market and the demands of clients. Therefore, with a clear orientation toward the needs of our clients, Dagartech has established itself as one of the main manufacturers of the Spanish market. The company currently has a stable presence in over 30 countries, with exports making up the main volume of its business.

The company has committed to innovation and has built up a human team with extensive experience in the energy generation sector. Quality and excellence form part of its present and pave the way for its future, which involves the company being certified on compliance with the requirements of the ISO 9001:2015 standard.