- Generator setsBack

By range

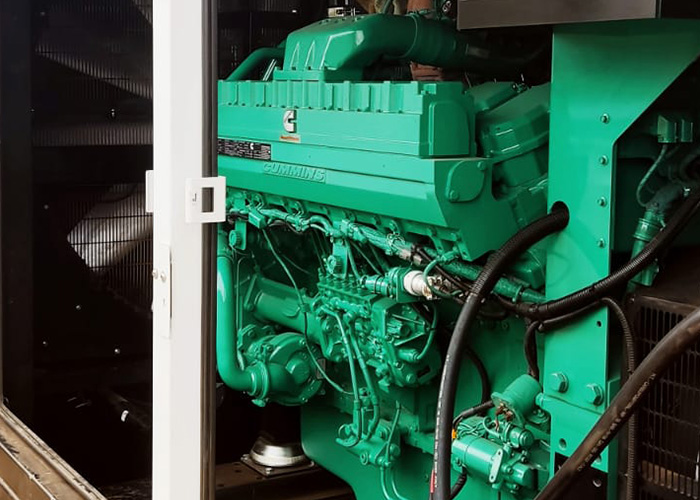

DIESEL RANGES

GASOLINE RANGES

By power

Low power (from 2kVA to 25 kVA) Medium power (from 30kVA to 770 kVA) High power (over 825 kVA)

Customized generator sets

More informationWe transform your needs into technical specifications and design and manufacture your genset 100% customised.

- Custom generator sets

- Applications

- Technical assistance